FIXED HALF BRIDGE CENTRALLY DRIVEN CLARIFIER

Equipment - Centrally driven Clarifier mechanism, suitable for installation in your R.C.C. Tank of suitable diameter, SWD and 0.50 meter FB generally as per the details given below :

- The mechaism would be of Central driven type, with the bridge spanning the tank radius, one end over the tank wall and the other over a Center mechanism cum turn table in the Center Pier. The feed may be brought into the tank through this pier. Iniemal gear cum worm drive type turn table resting over a mild steel base frame on the RCC center pier. (S type)

- Walkway cum driving bridge of 1000 mm wide with 1 meter high hand railings and 5 mm thick chequered plate walkway for the full length of bridge.

- Main drive consisting of a center mechanism with internal gears through which the scraper cage is hung. This internal gear in turn is run by a A Type worm drive head with drive pinion on output end.

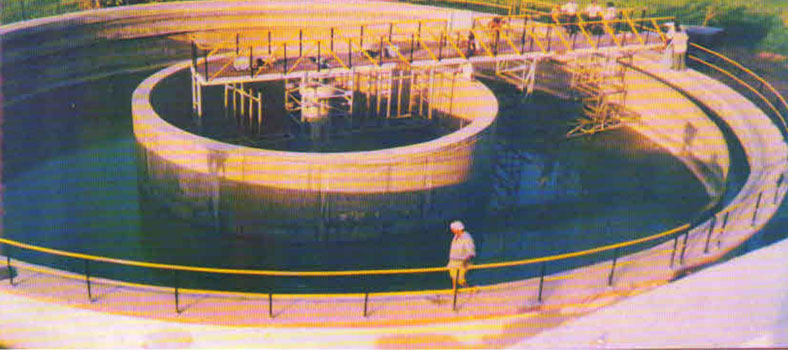

PERIPHERALLY DRIVEN CLARIFIER WITH INDEPENDENT FLOCCULATORS

Clariflocculator mechanism, suitable for installation in your R.C.C. Tank of size suitable diameter by side water depth, 0.30 meter Free board and having an R.C.C. Inner flocculation tank of size suitable diameter and centre water depth and R.C. Centre Pier of suitable diameter, generally as specified below.

The mechanism will be peripherally driven type, having the bridge spanning half the diameter of the tank and having two independent Flocculators at 180 degrees apart withrin the flocculation tank.

On the centre R.C.C. Pier of 900 mm, shall rest the stewing Ring type Turn Table of 900 mm diameter over a base plate. The base plate will be anchored to the R.C.C. Pier.

Bridge Centre Support shall rest over the turntable, The bridge will be connected to the bridge centre support through hinge pin / pivot arrangements, to ensure smooth running at uneven levels of R.C.C. Wall surface.

The bridges would be fabricated out of I.S.M.C. Channels or lattice bridge type constn, depending on the diameter_ The bridge will be effectively cross-braced for sturdiness and shall have a chequered plate walkway all over the length. There shall be hand railings of 1 meter high all along the two edges of the bridge, made out of 32 NB 25 NB 'Br class ERW pipes

SPECIFICATION FOR THICKENER

Heavy Duty Thickener Mechanism, centrally driven type suitable for installation in your R.C.C. Tank of suitable diameter, side water depth, 0.5 meter Free Board & with a slope of 1:8 at the bottom generally as specified below and consisting of the following components:

- Main bridge spanning the full diameter of the tank, and having 5 mm thick chequered plate walkway to the half length of the bridge.

- Hand Railing made out of 32 NB and 25 NB 'B' class ER W pipes, 1 meter tall, to half the length of the bridge.

- Main Drive Head of 1500 mm worm gear diameter.

Prime Drive to the drive head consisting of the following:

- Kirloskar I Crompton NGEFI Bharat Bijlee erqvt motor of 1,400 rpm, IID-55 protected.

- Elecon r Radicon/Shanthi worm gear reducer with a service factor of 1J5 & of suitable ratio.

- Lovejoy coupling between motor and reducer,

- Coupling guard.

- Sprocket and Chain drive, 1" pitch simplex system, between worm gear box and Drive Head.

- Chain guard.

HIGH RATE SOLID CONTACT CLARIFIER

Process Description

This Clarifier is a high rate, solids contact, sludge recirculation type clarifier, which, in minimum time and space and using a minimum amount of chemicals, produces an effluent of the highest quality. It is used principally for clarification, lime softening, silica reduction, or organics reduction of water and waste waters containing suspended solids, colors and organic impurities. As such it provides a means for chemical addition and mixing, flocculation and up flow clarification in a single unit. As a special case we can also add Tube settling or plate settling media for faster settling in the clarification zone We can provide this Clarifier with Ms Tank or can place the same on your Civil Tank,

Construction

HRSCC mechanism, suitable for installation in your RCC tank of size suitable and total depth, generally manufactured as per the below detailed specifications and designs. The same constitutes our scope of supply and from the major components of the equipment.

Bridge

Main bridge (Lattice type) spanning the full diameter of the tank will be made out of truss type fabricated MS structures and shall have a minimum of 1000mm width. It shal be firmly anchored on your RCC tank wall. Two more truss type structures shall be placed at 90 degrees to the bridge, spanning the tank diameter and duly anchored to the wall, to help suspend and hold the draft tube and detention hood. All These would he spliced for transportation.